Mitsui Kinzoku Low-Temperature Sintered Copper Powder: A versatile material in the fields of microelectronics and batteries

Mitsui Kinzoku Low-Temperature Sintered Copper Powder: A versatile material in the fields of microelectronics and batteries

Mitsui Kinzoku's low-temperature sintered copper powder is a type of metal powder with excellent performance, widely used in the manufacturing of electronic components, aerospace industry, and the field of renewable energy.

The low-temperature sintering copper powder from Mitsui Kinzoku in Japan is produced using advanced preparation techniques, mainly including chemical synthesis and physical methods. With the chemical synthesis method, copper ions are reduced to metallic copper through chemical reactions, and then copper powder is obtained through processes such as washing and drying. The physical method involves crushing and grinding copper blocks or copper wires to obtain copper powder. Both methods can provide copper powder with fine particle size and high purity.

The low-temperature sintering process is the core technology of Mitsui Kinzoku's low-temperature sintered copper powder. This process utilizes relatively low temperatures for sintering, allowing the copper powder to maintain excellent electrical conductivity while obtaining good mechanical and corrosion resistance properties. Furthermore, the low-temperature sintering process effectively controls the microstructure of the copper powder, enhancing its overall performance.

Properties of Low-Temperature Sintered Copper Powder

1. Physical Properties

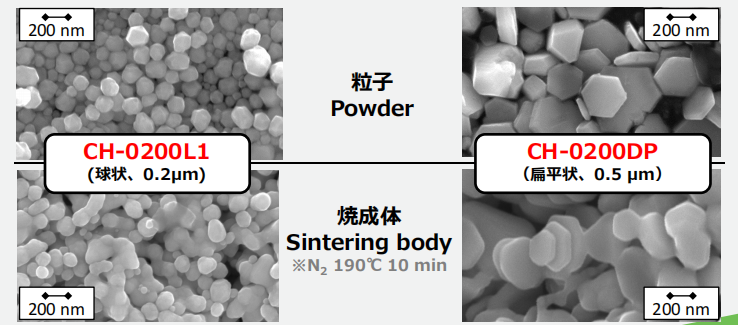

Mitsui Kinzoku's low-temperature sintered copper powder has two morphologies: flake-like and spherical. It possesses characteristics such as uniform particle size, good flowability, and high bulk density. It exhibits excellent electrical conductivity and thermal stability.

EMI:

2. Chemical Properties

Mitsui Kinzoku's low-temperature sintered copper powder demonstrates exceptional corrosion resistance and oxidation resistance. This copper powder starts to sinter at approximately 200°C and can be used in power devices. It can be sintered at the same temperature as silver powder. At high temperatures, this copper powder maintains stable chemical properties and is not prone to undergo chemical reactions with gases and substances in the surrounding environment.

Advantages of low-temperature sintered copper powder

High thermal conductivity

Mitsui Kinzoku's low-temperature sintered copper powder has excellent electrical conductivity, with higher conductivity than other metal powders. Therefore, in the manufacturing of electronic components, this copper powder can effectively improve the conductivity and stability of electronic devices.

High stability

In high-temperature environments, Mitsui Kinzoku's low-temperature sintered copper powder can maintain stable physical and chemical properties. This makes the copper powder have a wide range of applications in the aerospace and new energy fields.

Good mechanical properties

Mitsui Kinzoku's low-temperature sintered copper powder has good mechanical properties such as tensile strength, compressive strength, and wear resistance. This allows the copper powder to have high processing performance and yield during the manufacturing process.

Applications of low-temperature sintered copper powder

Electronic component manufacturing:

Mitsui Kinzoku's low-temperature sintered copper powder has a wide range of applications in electronic component manufacturing. For example, in the production of integrated circuits, this copper powder can be used for making pins and conductive layers. It can also be utilized in the production of thin film resistors as a resistance layer. Additionally, this copper powder can be used for manufacturing various electronic components such as sensors, switches, and connectors.

Chip bonding material: Low-temperature sintered copper powder can be used for reliable bonding between chips and substrates. This material possesses excellent conductivity and thermal conductivity, meeting the requirements of high-density chip packaging.

Wiring material: Low-temperature sintered copper powder can be used as wiring material in microelectronic devices. Its superior conductivity and corrosion resistance ensure stable signal transmission.

Electrode material: In energy storage devices such as batteries, low-temperature sintered copper powder can be utilized as an electrode material. It has high electrical conductivity and excellent mechanical properties, ensuring efficient charging and discharging of the battery."

Aerospace field:

In the aerospace field, Mitsui Kinzoku's low-temperature sintered copper powder is used in the manufacturing of various high-temperature electronic components and structural parts. For example, in the control systems and sensors of aircraft and rockets, this copper powder can be used to create conductive circuits and connectors. In engines and turbines, it can be utilized to produce high-temperature parts and seals. Additionally, this copper powder can be applied in the production of various structural and functional components in the aerospace industry.

Renewable energy filed:

In the field of renewable energy, with the continuous development of new energy technologies, the application of Mitsui Kinzoku's low-temperature sintered copper powder has also become increasingly widespread. For instance, in the production of solar panels, this copper powder can be used for creating conductive circuits and connectors. In the production of wind turbines, it can be used for manufacturing components such as conductive blades and bearings. Furthermore, this copper powder can be employed in the manufacturing of various electronic components and structural parts in electric vehicles and charging stations.