Nano Nickel Powder: An Essential Application Material Driving the Upgradation of the MLCC Industry.

Nano Nickel Powder: An Essential Application Material Driving the Upgradation of the MLCC Industry.

The Development Trends of MLCCs

With the continuous upgrades and improvements in electronic devices, the demand for MLCCs has been steadily increasing, aiming towards higher capacities, smaller sizes, lower costs, and wider application areas. According to market research reports, the global MLCC market is expected to maintain steady growth in the coming years, with key growth areas including automotive electronics, new energy, and 5G communications.

The Requirements of Nano Nickel Powder for MLCCs

During the manufacturing process of MLCCs, nano nickel powder is utilized as an internal electrode material. To meet the performance requirements of MLCCs, nano nickel powder needs to possess the following characteristics:

During the manufacturing process of MLCCs, nano nickel powder is utilized as an internal electrode material. To meet the performance requirements of MLCCs, nano nickel powder needs to possess the following characteristics:

☆ Particle Size: Nano nickel powder is required to have fine and uniform particle sizes to form dense electrode layers during the sintering process.

☆ Chemical Properties: Nano nickel powder needs to exhibit stable chemical properties to withstand high temperatures and chemical corrosion during sintering and processing.

☆ Conductivity: Nano nickel powder should demonstrate excellent conductivity to achieve high performance and low resistance in capacitors.

☆ Processability: Nano nickel powder is required to have good processability to enable high-precision and efficient production during the manufacturing process.

The Application of Nano Nickel Powder in MLCCs

Nano nickel powder is primarily used in MLCCs for manufacturing internal electrodes. It is mixed in an organic solvent to form a slurry, which is then applied to the ceramic dielectric, followed by sintering and metallization processes to create internal electrodes. Throughout this process, the particle size and chemical stability of nano nickel powder directly impact the consistency and reliability of the capacitor.

JFE Chemical Corporation's Ultrafine Nickel Powder

The ultrafine nickel powder produced by Japan's JFE using Chemical Vapor Deposition (CVD) technology is a black or dark gray powder characterized by:

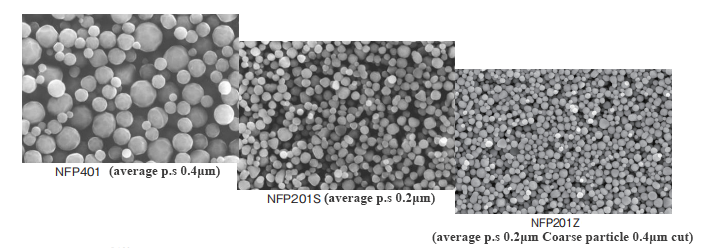

Spherical shape

Precisely controlled particle size: average particle size of 0.1~0.4μm

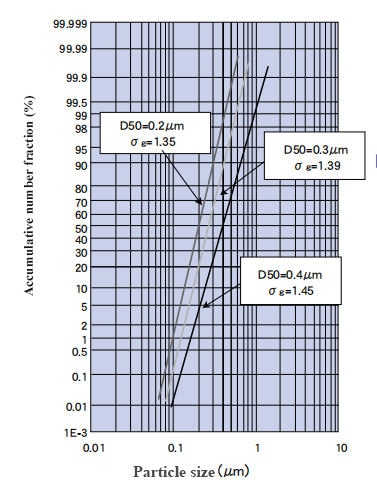

Concentrated particle size distribution: geometric standard deviation of 1.3~1.5

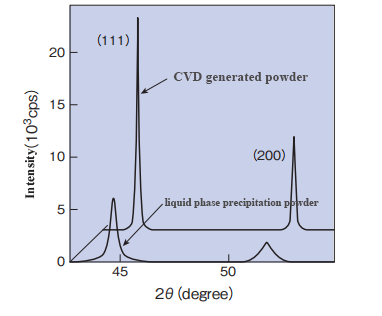

High crystallinity: average crystallite size >0.1μm

Stable surface oxide film: covered with an oxide film of approximately 3nm thickness

Smooth particle surface

High purity: Ni >99.9%

The Primary Applications of JFE Ultrafine Nickel Powder

Internal electrodes for MLCCs.

Electrode materials for other electronic components.

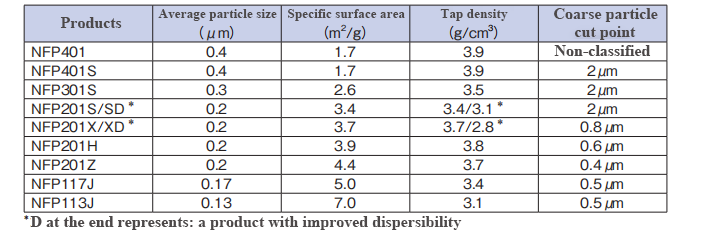

The main performance indicators of JFE Ultrafine Nickel Powder

The Particle Size Distribution of JFE Ultrafine Nickel Powder

The X-ray Diffraction Pattern of JFE Ultrafine Nickel Powder

Japan possesses a high level of technological expertise and extensive experience in the manufacturing of nano nickel powder. Their nano nickel powder boasts fine particle sizes, high purity, excellent conductivity, and stable chemical properties. It also demonstrates good dispersibility and superior processability, meeting the demands for high-precision and high-efficiency MLCC manufacturing. Japanese companies emphasize material selection and stringent quality control systems to ensure the stability and consistency of nano nickel powder. These advantages render Japanese nano nickel powder highly competitive in the market.

The Current Supply Situation of Domestic Nano Nickel Powder

The production and application of domestic nano nickel powder are still in their initial stages, with a relatively weaker supply capacity. In recent years, driven by the continuous development of domestic science and technology alongside the growth in demand from the electronics industry, the production volume and quality of domestic nano nickel powder have been steadily improving. However, there still exists a certain gap between domestically produced nano nickel powder and imported ones in terms of product variety, quality stability, and expansion in application areas.

As a distributor of fine chemical products, Beijing Entrepreneur offers JFE's nano nickel powder specifically designed for MLCCs.