Preparation Techniques of Ultrafine Copper Powder for HJT Silver-Coated Copper.

Preparation Techniques of Ultrafine Copper Powder for HJT Silver-Coated Copper.

Photovoltaic cells, more commonly known as solar cells, are devices capable of directly converting sunlight into electrical energy, serving as a core component of solar power generation systems. With the increasing demand for renewable energy sources, the solar industry has experienced rapid development. However, the manufacturing cost of solar cells remains relatively high, which has hindered their widespread adoption and application globally. Therefore, reducing costs and increasing efficiency have become the intrinsic logic driving the continuous iteration of solar cells.

In the manufacturing process of solar cells, silver paste is one of the key conductive materials used for electrode fabrication and circuit connections. However, silver is a precious metal with high costs, and the significant amount of silver paste used accounts for a substantial portion of the manufacturing cost of solar cells. Consequently, reducing the usage of silver paste or finding alternative materials has become crucial for cost reduction in solar cell production.

Cheap metal-coated silver powders are composite metal powder materials prepared using advanced surface treatment technologies. By depositing different thicknesses of silver layers on the surface of copper micro-nanoparticles, the antioxidative properties and conductivity of copper powders are enhanced. This material can serve as an alternative to silver paste in solar cells, effectively reducing manufacturing costs.

HJT (Heterojunction) cells are a novel solar cell technology known for their high efficiency, low degradation, and excellent stability. In HJT cells, silver-coated copper powder serves as an alternative material to silver paste, further improving the conductivity and stability of the cells while reducing manufacturing costs. The market demand for ultrafine copper powder, one of the primary raw materials for silver-coated copper powder, is also steadily increasing.

Ultrafine copper powder possesses characteristics such as small particle size, large surface area, and high reactivity, making it widely applicable in areas such as solar cells, conductive coatings, electronic pastes, among others. There are five main preparation techniques for ultrafine copper powder.

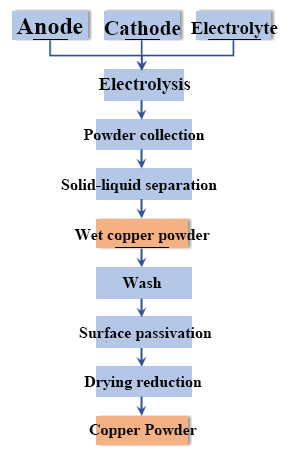

1. Electrolysis Technique

Preparation Principle: Electrolysis technique is a common method for preparing ultrafine copper powder. In this process, refined copper plates are used as anodes, copper plates as cathodes, and copper sulfate and sulfuric acid solution as electrolytes. When current passes through this system, copper dissolves from the anode into the electrolyte and deposits onto the cathode, forming copper powder. The advantage of the electrolysis method is its simple equipment, convenient operation, scalability for mass production, high purity, and fine particle size of the resulting copper powder.

Preparation Process:

Process Characteristics: Low cost, easy process control, good batch stability.

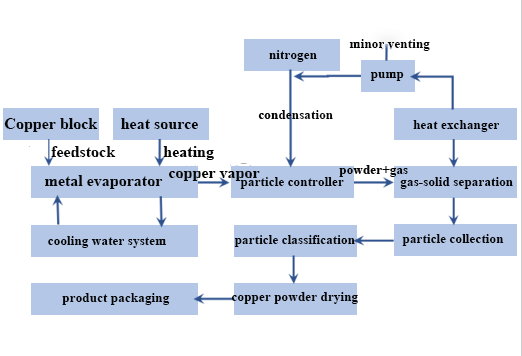

2. Gas Phase Deposition Technique

Preparation Principle: Gas phase deposition technique involves heating metal raw materials to melt and evaporate, forming metal vapor, and then cooling and condensing the metal vapor into metal powder under specific environmental conditions. This process can be achieved through resistance heating, high-frequency induction heating, or plasma heating. During the cooling of the metal vapor, metal powder is formed, which is then collected and classified into different specifications of copper powder through gas-solid separation. Copper powder prepared by gas phase deposition technique has advantages such as high purity, uniform particle size, and good sphericity.

Preparation Process:

Process Characteristics: High sphericity of copper powder, good batch stability.

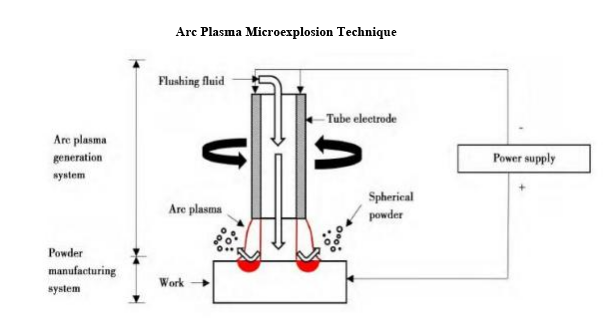

3. Arc Plasma Microexplosion Technique

Preparation Principle: Arc plasma microexplosion technique utilizes the high temperature and high energy density characteristics of arc plasma to instantly melt, vaporize, and explode the metal, thereby preparing metal powder. In this process, a strong pulse current is generated in the metal conductor under the action of high voltage, causing the metal to melt, vaporize, and expand rapidly, producing shockwaves. The metal vapor moves at high speed under the drive of shockwaves, sometimes undergoing chemical reactions with the medium, and then rapidly cools under the collision of the medium, forming metal powder. Copper powder prepared by arc plasma microexplosion technique has advantages such as fine particle size, high sphericity, and high surface activity.

Preparation Method:

Process Characteristics: Wide adaptability of materials, low energy consumption, small equipment investment.

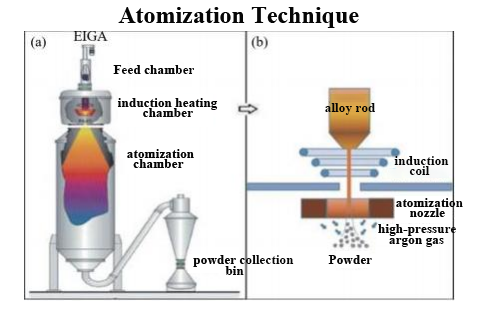

4. Atomization Technique

Preparation Principle: Atomization technique involves breaking liquid metal or alloy into fine droplets under the action of external forces (such as water flow or airflow) and quickly solidifying to form powder. The diameter of the powder is usually less than 150μm. During the preparation process, liquid metal or alloy is first atomized into fine droplets, which rapidly condense upon contact with a cold environment, forming powder. Subsequently, the collected powder needs to be dried and sieved to obtain spherical powder with different grades. Copper powder prepared by atomization technique has advantages such as high purity, uniformity, and density.

Preparation Method:

Process Characteristics: Low cost, wide adaptability of materials.

5. Liquid Phase Reduction Technique

Preparation Principle: Liquid phase reduction technique is a method of reducing divalent copper ions to zero-valent copper powder in a liquid or quasi-liquid environment using reducing agents (such as hydrazine hydrate, ascorbic acid, glucose, etc.). During liquid phase reduction, copper ions in the solution react with reducing agents to generate copper powder. By controlling reaction conditions such as temperature, pH, type, and concentration of reducing agents, copper powder with specific morphology and particle size can be prepared. Liquid phase reduction technique has advantages such as simple operation, fast reaction rate, and ease of industrial production, making it an important method for preparing ultrafine copper powder.

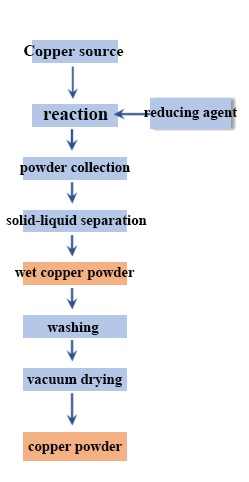

Preparation Process:

Process Characteristics: Controllable particle size, narrow particle size distribution, simple equipment, relatively low cost.

Comparative Analysis of Various Methods for Preparing Ultrafine Copper Powder

|

Preparation Techniques |

Advantages |

Disadvantages |

|

Electrolysis |

easy process control, dendritic powder, large specific surface area, low bulk density conducive to pressing and molding |

Difficulty in application in HJT paste. |

|

Gas Phase Deposition |

The powder has high sphericity and smooth surface, capable of achieving micrometer and submicrometer particles, suitable for HJT silver-copper slurry. |

Due to limitations of powder classification equipment, the powder Span value is relatively large. |

|

Arc Plasma Microexplosion |

Capable of achieving micrometer and submicrometer particles. |

The powder surface is uneven, limited by powder classification equipment, resulting in a relatively large powder Span value. |

|

Atomization |

The gas atomized copper powder has high sphericity, can achieve micrometer particles, suitable for HJT silver-copper slurry. |

Due to limitations of powder classification equipment, the powder Span value is relatively large. |

|

Liquid Phase Reduction |

The particles are uniform with a narrow distribution, and the powder Span value is less than 0.8, eliminating the need for classification. They possess multiple crystal facets, making them suitable for HJT silver-copper slurry. |

The powder surface is uneven, with a small amount of organic residue. |

As a distributor of fine chemical products, Entrepreneur offers high-quality domestically produced ultrafine copper powder using liquid-phase reduction technology. Our product is technologically advanced and suitable for HJT silver-coated copper powder, allowing you to reduce costs, increase efficiency, and gain a competitive edge.