The application of ultrafine copper powder produced by liquid-phase reduction method in the preparation of silver-coated copper powder.

The application of ultrafine copper powder produced by liquid-phase reduction method in the preparation of silver-coated copper powder.

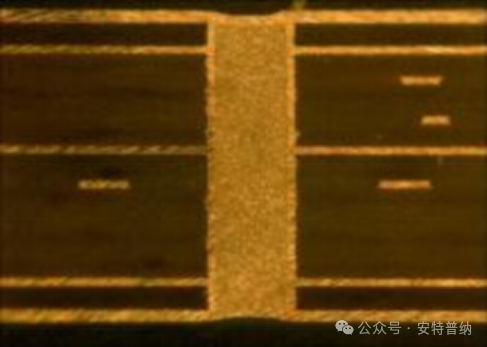

In the modern electronics industry, silver-coated copper powder has attracted considerable attention due to its unique electrical and thermal conductivity properties. As a high-performance electronic material, the choice of preparation process is particularly important. Entrepreneur's liquid-phase reduction ultrafine copper powder, as a high-quality material, has demonstrated advantages in the process of preparing silver-coated copper powder.

Compared to traditional atomized copper powder, liquid-phase reduction copper powder has higher particle size uniformity, with a SPAN value less than 0.9, eliminating the need for additional classification processing. This higher uniformity is crucial for the subsequent uniformity of the silver layer. In contrast, atomized copper powder is constrained by powder classification equipment during the preparation process, typically resulting in a SPAN value greater than 1.2, which significantly affects the quality stability of silver-coated copper powder.

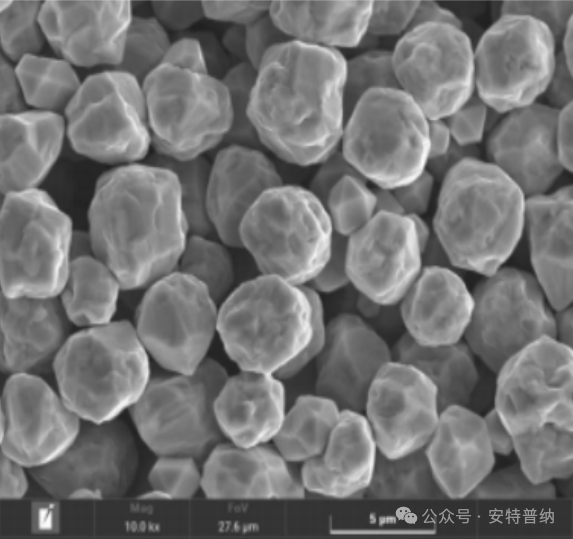

Furthermore, the polycrystalline surface structure of liquid-phase reduced copper powder is also a major highlight. This structure allows for a larger contact surface area of the copper powder in the slurry, thereby enhancing its bonding capability with the silver layer. When the copper powder is enveloped by the silver layer, the polycrystalline surface structure ensures a lower contact resistance between the silver layer and the copper powder, thereby improving the conductivity of the silver-coated copper powder. This advantage is particularly important in the preparation of high-performance electronic materials, as it directly relates to the efficiency and stability of electronic devices.

The main characteristics of liquid-phase reduced ultrafine copper powder

Unique wet preparation technology

Liquid-phase reduction method is a technique for preparing metal powders through reduction reactions in a liquid medium. This method involves the reaction of metal ions with a reducing agent in a solution, resulting in the precipitation of metal atoms to obtain metal powder. Ultrafine copper powder prepared by wet methods exhibits high dispersibility, meaning that the powder particles are uniformly dispersed in the solution and are less prone to aggregation. This high dispersibility facilitates the uniform distribution and good bonding of copper powder in composite materials. Additionally, wet preparation can yield copper powder with high filling properties, meaning a higher content of copper powder per unit volume. This helps improve the electrical conductivity, thermal conductivity, and mechanical properties of composite materials. Furthermore, copper powder prepared by the liquid-phase reduction method also features a narrow particle size distribution. This means that the particle sizes of the copper powder are relatively uniform, contributing to the stability and consistency of composite materials.

Unique hydrophilic flake process

In the process of preparing copper powder by liquid-phase reduction method, hydrophilic flake copper powder can be obtained through special process control. This type of flake copper powder has hydrophilic groups on its surface, which readily combine with water molecules, thereby exhibiting excellent hydrophilicity. Hydrophilic flake copper powder has significant advantages in the processing of composite metal powders. Due to its unique flake structure and high specific surface area, it can improve the electrical conductivity, thermal conductivity, and mechanical properties of composite metal powders. Additionally, hydrophilic flake copper powder can also improve the processing performance of composite metal powders, such as flowability, moldability, and sinterability.

Customizable particle size and thickness

In the process of preparing copper powder by liquid-phase reduction method, the particle size and thickness of copper powder can be precisely controlled by adjusting reaction conditions, raw material concentration, and type of reducing agent. This means that copper powder with different particle sizes and thicknesses can be customized according to specific customer requirements. Copper powders with different particle sizes and thicknesses have different advantages in applications, aiming to achieve better electrical conductivity, thermal conductivity, mechanical properties, and stability of composite materials.

Shaping process for improved sphericity

To meet customer requirements for sphericity, a shaping process has been added during the preparation of ultrafine copper powder by liquid-phase reduction method. This shaping process involves grinding and refining the copper powder particles to make them more spherical in shape. Improving sphericity is beneficial for enhancing the dispersibility and flowability of copper powder in composite materials. Additionally, spherical copper powder exhibits better packing performance and higher filling density, which helps improve the electrical conductivity, thermal conductivity, and mechanical properties of composite materials. The shaping process also reduces friction and collisions between copper powder particles, thereby reducing loss and defects in composite materials during processing.

The main indicators of ultrafine copper powder prepared by liquid-phase reduction method.

|

Grade |

Morphology |

Particle size distribution (um) |

Bulk density (g/cm3) |

Tapped density (g/cm3) |

Moisture (%) |

Specific surface area (m2/g) |

||

|

D10 |

D50 |

D90 |

||||||

|

ATPN-C-1 |

Spherical |

≥ 0.5 |

1.5~2.5 |

≤3.5 |

2.0~2.4 |

3.8~4.3 |

≤ 0.2 |

0.8~0.9 |

|

ATPN-C-1A |

Spherical |

≥2.0 |

3.8~4.2 |

≤7.0 |

3.0~3.5 |

4.5~4.8 |

≤ 0.2 |

0.3~0.4 |

|

ATPN-C-1A (Spheroidized) |

Spherical |

≥2.0 |

3.8~4.2 |

≤7.0 |

3.0~3.5 |

4.5~4.8 |

≤0.2 |

0.3~0.4 |

|

ATPN-C-2 |

Spherical |

≥2.5 |

5.0~6.0 |

≤10.0 |

3.0~3.5 |

4.5~4.8 |

≤ 0.2 |

0.25~0.3 |

|

ATPN-C-2 (Spheroidized) |

Spherical |

≥2.5 |

5.0~6.0 |

≤10.0 |

3.0~3.5 |

4.5~4.8 |

≤0.2 |

0.25~0.3 |

|

ATPN-PC-1 |

Flake |

≥2.0 |

3.0~4.0 |

≤7.0 |

2.0~2.5 |

4.2~4.6 |

≤0.2 |

0.4~0.5 |

|

ATPN-PC-2 |

Flake |

≥4.0 |

6.5~7.5 |

≤12 |

2.4~2.7 |

4.5~5.0 |

≤0.2 |

0.35~0.4 |

As a distributor of fine chemical products, Entrepreneur offers high-quality domestically produced ultrafine copper powder prepared by the liquid-phase reduction method. This product is technologically advanced and can be used for various purposes, including the preparation of silver-coated copper powder. Please vist our product page 99.9% Copper Powder Cu powder CAS | Entrepreneur (entrepn.com) for more information.