The key to the advancement of electronic devices lies in flexible silver paste.

The key to the advancement of electronic devices lies in flexible silver paste.

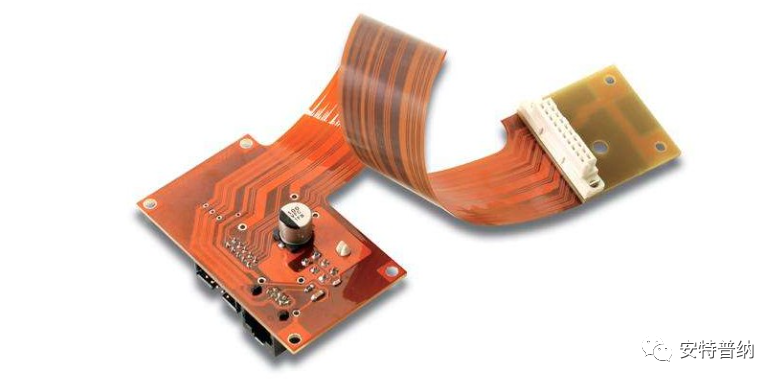

With the rapid development of technology, Flexible Printed Circuits (FPC) are being increasingly utilized across various electronic devices, and flexible silver paste plays a crucial role in this process. In portable devices like smartphones, tablets, and more, flexible silver paste is used to create bendable screens and various internal circuits. In wearable tech, it's employed in crafting flexible circuits and sensors. In the automotive and aerospace industries, flexible silver paste is used for creating highly durable circuits and connectors.

Flexible silver paste is a special conductive material composed of silver particles and an organic carrier, possessing excellent conductivity and flexibility. Widely used in the production of flexible printed circuits, it creates conductive paths and connects various electronic components.

Conductive paths are crucial components within electronic devices, responsible for transmitting currents and guiding signals. When made with flexible silver paste, these paths exhibit outstanding conductivity and durability, ensuring the normal operation of electronic devices. Moreover, flexible silver paste is used for interconnecting electronic components, allowing effective integration into a complete circuit system.

Its application spans across various devices including but not limited to smartphones, laptops, tablets, digital cameras, players, and other electronic products featuring flexible circuit boards. Beyond traditional electronic devices, it finds utility in fields such as new energy vehicles, the Internet of Things (IoT), medical devices, and more. As electronic devices continue to become smaller and lighter, the prospects for flexible silver paste are expanding. As a critical material for flexible printed circuits, it plays an increasingly important role in electronic devices. Its excellent conductivity and flexibility enable the realization of smaller, lighter, and more flexible designs for electronic devices. With continuous technological advancements, the application scope of flexible silver paste will broaden, consequently increasing the demand for silver powder.

Thick-film conductive adhesive is an adhesive used for connecting electronic components, and silver powder is a commonly used filler in this adhesive.

The application of silver powder in thick-film conductive adhesive can be summarized as follows:

1. Enhancing conductivity: Silver powder has a low resistivity, is resistant to oxidation, and even if oxidized, its oxide product maintains good conductivity. Therefore, adding silver powder to thick-film conductive adhesive significantly improves its conductivity.

2. Increasing thermal conductivity: The addition of silver powder in thick-film conductive adhesive aids in heat dissipation, enhancing its thermal conductivity.

3. Improving bonding strength: Silver powder in thick-film conductive adhesive also acts as a bonding phase, improving the strength of the bonding layer between components.

The application of silver powder in thick-film conductive adhesive can enhance the conductivity, thermal conductivity, and bonding strength of the adhesive layer, thereby improving the connection efficiency and lifespan of electronic components.

Entrepreneur has established long-term collaborations with leading metal powder suppliers in Japan and domestically, providing stable raw material supply and professional technical support for the research and development of flexible silver paste and thick-film conductive adhesive products.

The dendritic silver powder from Mitsui Metal

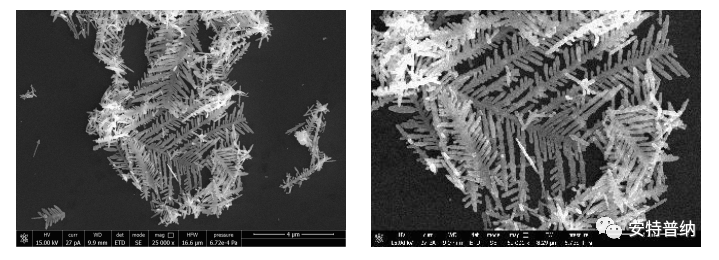

Mitsui Metal utilizes proprietary technology to produce dendritic silver powder with low apparent density. Compared to traditional silver powders (spherical, flake), this dendritic silver powder exhibits conductivity with a lower filler addition, consequently reducing the cost of flexible silver paste.

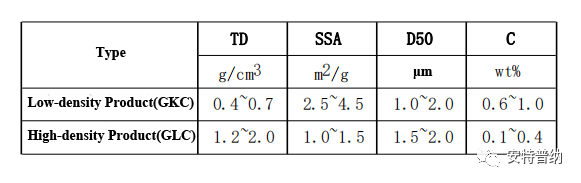

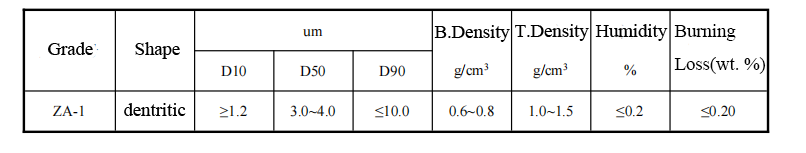

Mitsui Metal offers two types of silver powder with different densities, with the following main performance indicators:

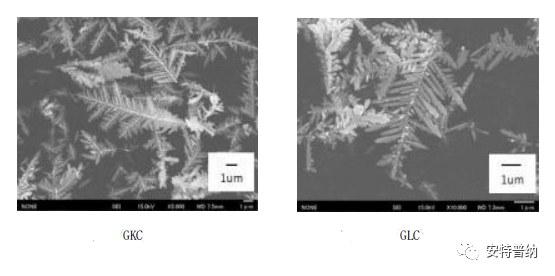

SEM

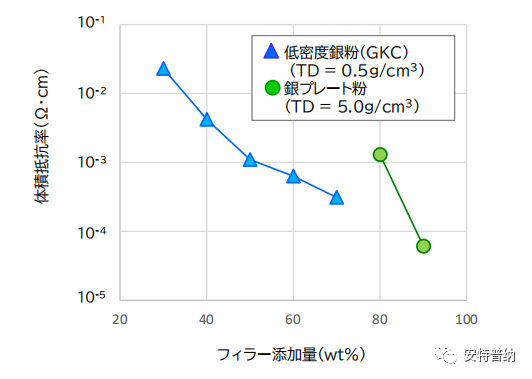

The relationship between filler addition rate and film conductivity:

The test results indicate that:

1. Conductivity is achieved with a minimal amount of filler (reduced filler usage).

2. Due to increased resin segregation, the flexibility and adhesion properties of the resin are well retained on thin films and coatings.

Primary applications include:

1. Flexible silver paste

2. Flexible Printed Circuit (FPC) silver paste.

Domestically produced high-quality dendritic silver powder

Silver Powder ZA-1

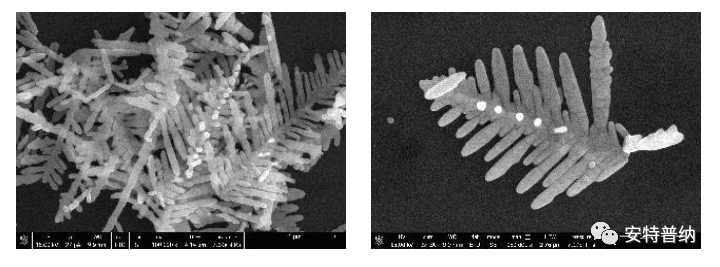

Product Overview: Ultrafine dendritic silver powder with a dendritic morphology, exhibiting excellent conductivity.

Performance indicators of ZA-1:

SEM

Primary applications include:

1. Flexible circuit silver paste

2. Thick-film conductive adhesive

3. Electromagnetic shielding, etc.