Product Description

Alumina Sol Nanopowder / Pseudoboehmite Nanoparticles for Aluminum Sol

-

Not Applicable

-

ATPN-AS-2N01L/2N01L/2N01G/2N11G/2.5N01L/2.5N02L/2.5N01G/2.5N02G/3.5N01L

-

Entrepreneur

-

White powder

-

90%?99%

Product name: Alumina Sol Nanopowder / Pseudoboehmite Nanoparticles for Aluminum Sol

Brand: Entrepreneur

Cas No.: Not Applicable

Grade: ATPN-AS-2N01L/2N01L/2N01G/2N11G/2.5N01L/2.5N02L/2.5N01G/2.5N02G/3.5N01L/3.5N01G/4N01L/4N01G

Appearance: White powder

MOQ: 100g

Other names: AlOOH Nanopowder / AlOOH Nanoparticles / Aluminum Oxyhydroxide Nanopowder / Aluminium hydroxide oxide Nanoparticles

Description:

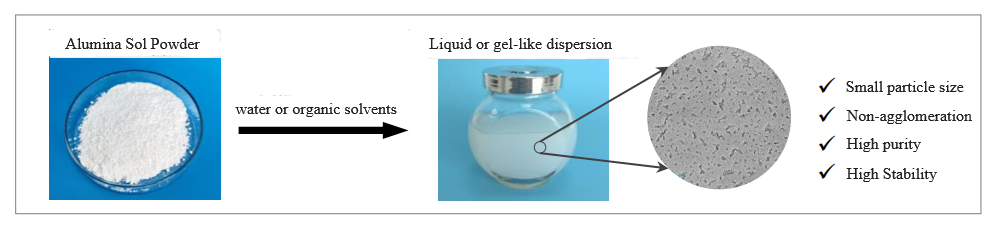

This series of products consists of boehmite-type nano-hydrated alumina sol powders, with a wide variety of types available. The products exhibit good flowability, large surface area, high purity, excellent stability, and strong adsorption properties. They can be dispersed in solvents such as water, methanol, ethanol, etc., to form liquid or colloidal dispersions. The dispersions feature small nanoparticle size, high transparency, and strong adhesiveness.Features:

1. Complete Range: Offers nano-alumina sol powders in types such as nitrate, hydrochloric acid, acetic acid, etc.;

2. Controllable Purity: The purity of hydrated alumina in the product can be stably controlled between 99% and 99.99%;

3. Monodispersity: Can be 100% completely dispersed in solvents to form liquid or colloidal dispersions;

4. Wide Solvent Compatibility: Can be dispersed in liquid solvents such as water, methanol, ethanol, isopropanol, etc.;

5. Uniform and Controllable Particle Size: Hydrated alumina nanoparticles have small, uniform sizes that can be precisely controlled.

Applications:

1. Alumina SolUsed for producing high-performance alumina sol in liquid and colloidal dispersion forms. It is freshly prepared for use, convenient, and highly effective.

2. Ink Absorption Materials

Leveraging the excellent fluidity, easy dispersion, and fast ink absorption speed of this product series, it is applied in inkjet printing materials such as RC photo paper, backlit films, wide-format prints, and films. Suitable substrates include PE, PP, PET, PVC, etc.

3. Additives

As an additive, it can be used in industries such as coatings, paints, ceramics, textiles, paper-making, polymers, and fillers.

4. New Energy

Used in new energy applications, such as coating battery separators and surface coating of electrode materials.

5. Catalyst

As an aluminum source or binder, it is used for synthesizing catalyst carriers with various shapes and structures.

6. Other Applications

Applied in industries such as abrasives, greenhouse plastic films, anti-static materials, refractory materials, and surface friction enhancement.

Specification:

|

Grades |

Indicators |

||||||||

|

Al2O3 Content (Dry basis) |

Al2O3 Content |

Crystal Size |

SiO2 |

Fe2O3 |

Na2O |

BET |

Pore Volume |

Remarks |

|

|

% |

% |

nm |

% |

% |

% |

m2/g |

mL/g |

- |

|

|

ATPN-AS-2N01L |

≥80 |

≥99 |

10-15 |

≤0.3 |

≤0.05 |

≤0.3 |

≥200 |

≥0.3 |

Following products can be customized: 1. Powder products of types such as nitrate, hydrochloric acid, acetic acid, etc.; 2. Powder materials that can be dispersed in liquids like water, methanol, ethanol, isopropanol, etc.; 3. Powder materials with different particle sizes, purities, and dispersibility. The letter 'G' in the grade number indicates that it forms a gel-like colloidal dispersion after being mixed with water, while the letter 'L' indicates that it forms a liquid after being mixed with water. The 'L' type is suitable for most users. |

|

ATPN-AS-2N11L |

≥80 |

≥99 |

10-15 |

≤0.3 |

≤0.05 |

≤0.1 |

≥200 |

||

|

ATPN-AS-2N01G |

≥80 |

≥99 |

15-20 |

≤0.3 |

≤0.05 |

≤0.3 |

≥200 |

≥0.3 |

|

|

ATPN-AS-2N11G |

≥80 |

≥99 |

15-20 |

≤0.3 |

≤0.05 |

≤0.1 |

≥200 |

≥0.3 |

|

|

ATPN-AS-2.5N01L |

≥80 |

≥99.5 |

5-10 |

≤0.1 |

≤0.03 |

≤0.08 |

≥240 |

≥0.35 |

|

|

ATPN- AS-2.5N02L |

≥80 |

≥99.5 |

10-15 |

≤0.1 |

≤0.03 |

≤0.08 |

≥240 |

≥0.35 |

|

|

ATPN-AS-2.5N01G |

≥80 |

≥99.5 |

10-15 |

≤0.1 |

≤0.03 |

≤0.08 |

≥240 |

≥0.35 |

|

|

ATPN-AS-2.5N02G |

≥80 |

≥99.5 |

15-20 |

≤0.1 |

≤0.03 |

≤0.08 |

≥240 |

≥0.35 |

|

|

ATPN-AS-3.5N01L |

≥80 |

≥99.95 |

10-15 |

≤0.01 |

≤0.01 |

≤0.01 |

≥240 |

≥0.4 |

|

|

ATPN-AS-3.5N01G |

≥80 |

≥99.95 |

15-20 |

≤0.01 |

≤0.01 |

≤0.01 |

≥240 |

≥0.4 |

|

|

ATPN-AS-4N01L |

≥80 |

≥99.99 |

10-15 |

≤0.008 |

≤0.008 |

≤0.008 |

≥240 |

≥0.4 |

|

|

ATPN-AS-4N01G |

≥80 |

≥99.99 |

15-20 |

≤0.008 |

≤0.008 |

≤0.008 |

≥240 |

≥0.4 |

|