Product Description

Graphene-coated Copper Powder

-

7440-50-8/1034343-98-0

-

ATPN GC-06/ATPN-35/ATPN-300m

-

Entrepreneur

-

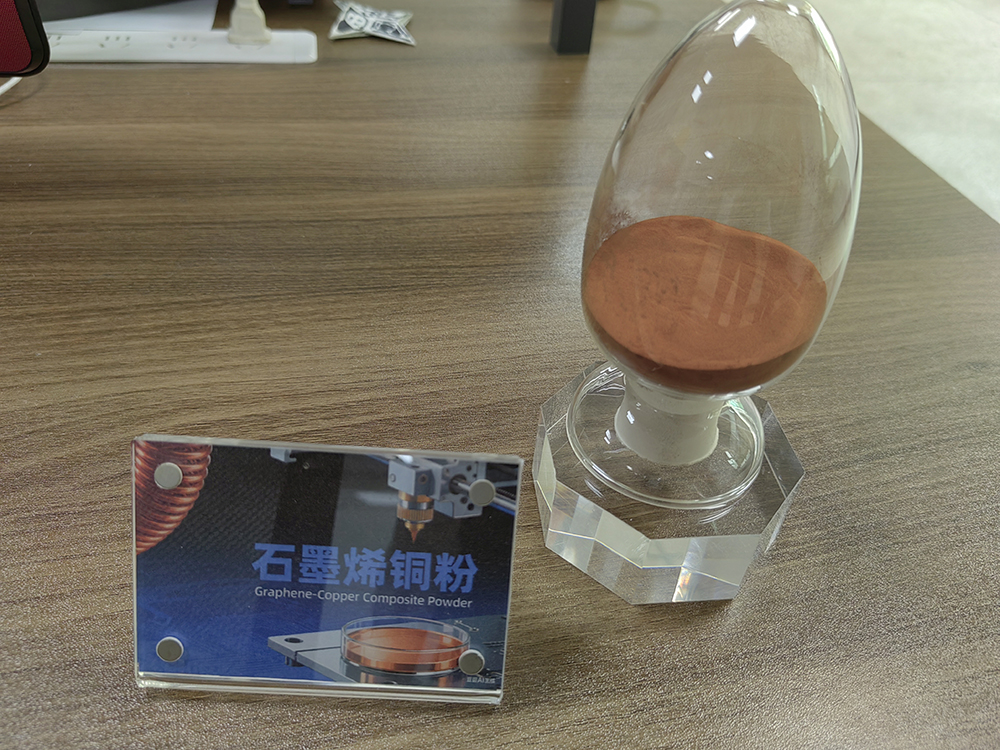

Reddish-Brown Powder

-

99.9% min

Graphene-Coated Copper Powder

High-Conductivity, High-Thermal Conductivity, Anti-Oxidation Material Specialized for 3D Printing and Electronic Components

##I. Core Product Advantages

Graphene-coated copper powder is an innovative composite material that integrates graphene and high-purity copper. It addresses industry pain points of traditional copper powder—such as oxidation, insufficient thermal conductivity, and interface scattering—through advanced coating technology, and empowers the upgrading of multiple fields with three core characteristics.

1. **Effective Anti-Oxidation Protection**

The two-dimensional crystalline structure of graphene forms a dense coating on the surface of copper powder, isolating it from oxygen contact. This significantly reduces the oxidation rate, extends the material's shelf life, and lowers production losses and enterprise costs.

2. **Optimized Interface Conduction Efficiency**

It fills in the uneven defects on the copper powder surface, enabling closer and more uniform particle contact. This substantially reduces interface scattering during electron and thermal conduction, creating a smooth conduction path.

3. **Synergistic Performance Enhancement**

Combining the basic electrical and thermal conductivity of copper with the exceptional properties of graphene, it achieves a "1+1>2" synergistic effect. Both electrical conductivity and thermal conductivity are significantly higher than those of traditional copper powder.

## II. Typical Application Fields

1. **3D Printing**

It solves the industry challenge of high laser reflectivity and difficulty in melting pure copper. Graphene's excellent photothermal conversion capability improves laser absorption rate, allowing copper powder to melt quickly and uniformly. The printing process is stable and efficient, with finished products featuring high precision and superior performance. It is suitable for manufacturing complex copper components in aerospace, automotive manufacturing, and other fields.

2. **Conductive Paste**

It enhances the conductivity between paste particles, optimizes electrical contact performance, and ensures stable current transmission. Graphene coating effectively delays oxidation, extending the paste's shelf life. It can partially replace precious metals like silver, and is used in conductive adhesives for electronic packaging and contact pastes for photovoltaic cells, significantly reducing production costs.

3. **Thermal Conductivity and Heat Dissipation Scenarios**

With excellent thermal conductivity and stable thermal resistance, it enables continuous and efficient heat dissipation in high-temperature environments. It is applicable to high-power radar T/R modules, new energy vehicle motor control systems, and other equipment, providing reliable heat dissipation support for core components and improving the operational stability and service life of equipment.

4. **Electronic Components and Flexible Electronics**

In the sintering of MLCC electrodes, it precisely controls the shrinkage rate and improves dimensional accuracy. When used in printed conductive inks and flexible sensors, it enhances adhesion to substrates and ensures stable conductive paths during bending and folding, facilitating the upgrading of products such as wearable devices and flexible screens.

5. **5G Communication Field**

It reduces high-frequency resistance and signal loss, and dissipates heat quickly, meeting the high heat generation and high transmission requirements of 5G equipment. When applied to flexible circuit boards, it optimizes the coefficient of thermal expansion and reduces temperature stress, helping equipment achieve miniaturization, lightweight design, and high performance.

## III. Product Technical Parameters

(Note: All parameters are verified through professional testing; actual data shall be subject to batch test reports.)

|

Model |

Copper Content |

Density Parameter |

Resistivity |

Morphology |

Particle Size Distribution (D10/D50/D90) |

|

ATPN GC-06 |

99.9% |

Tap density: 5.3g/cm3 |

0.156×10?3Ω·cm |

Spherical |

4.461μm/6.850μm/9.944μm |

|

ATPN-35 |

99.9% |

Tap density: 4.39g/cm3 |

0.39×10?3Ω·cm |

Spherical |

22.632μm/35.424μm/54.545μm |

|

ATPN-300m |

99.8% |

Bulk density: 1.79g/cm3 |

0.22×10?3Ω·cm |

Dendritic |

Tyler sieve analysis: +200 mesh 0-5% / +325 mesh 10-20% / -325 mesh (main component) |

## IV. Product Selection Recommendations

|

Grades |

Core Advantages |

Applicable Sub-Fields |

|

ATPN GC-06 |

1. High purity (copper content: 99.9%), extremely low resistivity (0.156×10?3Ω·cm), excellent electrical and thermal conductivity; 2. Spherical morphology + fine particle size (4.461-9.944μm), good dispersibility and molding stability; 3. Tap density: 5.3g/cm3, specific surface area: 0.23㎡/g, suitable for high-precision processing needs |

1. 3D Printing: Precision copper components for aerospace, small complex structural parts; 2. Conductive Paste: Front/back contact pastes for photovoltaic cells, conductive adhesives for electronic packaging; 3. Thermal Dissipation: High-power radar T/R modules, new energy vehicle electronic control systems; 4. 5G Communication: Miniaturized high-precision 5G components, micro flexible electronic devices |

|

ATPN-35 |

1. High purity (copper content: 99.9%), spherical morphology, good fluidity (15s/50g), high processing efficiency; 2. Large particle size (22.632-54.545μm), tap density: 4.39g/cm3, suitable for mass production; 3. Coefficient of thermal expansion can be optimized through formula adjustment to reduce temperature stress |

1. 3D Printing: Large copper components in automotive manufacturing, structural parts for mass production; 2. Thermal Dissipation: Filling for heat dissipation modules of large industrial equipment; 3. 5G Communication: Flexible circuit boards, 5G equipment components requiring matching of thermal expansion coefficient of parts |

|

ATPN-300m |

1. Unique dendritic morphology, strong adhesion, suitable for flexible substrates; 2. Mainly composed of -325 mesh particles, bulk density: 1.79g/cm3, good molding compactness; 3. Resistivity: 0.22×10?3Ω·cm, stable electrical conductivity |

1. Flexible Electronics: Conductive inks for wearable devices, sensors for flexible screens; 2. Thermal Dissipation: Flexible heat dissipation devices, heat dissipation scenarios requiring enhanced substrate bonding; 3. Micro Devices: Small flexible electronic components with high flexibility requirements; 4. Traction motor winding wires |