Product Description

Liquid Crystal Epoxy Resin / LCER

-

N/A

-

ATPN-LCER

-

Entrepreneur

-

Clear liquid

-

85% min

Description

Liquid Crystal Epoxy Resin stands out due to its unique combination of liquid crystal molecular order and epoxy resin properties, offering superior mechanical, thermal, optical, and electrical performance. It is particularly suited for high-performance, high-precision applications.

Key features of LCER

1. Liquid Crystal Properties

· Ordered Molecular Arrangement: LCER molecules exhibit a liquid crystalline state under specific conditions (e.g., temperature, pressure, or electric fields), with highly ordered molecular alignment (like crystals) while maintaining fluidity (like liquids). This order can be partially retained after curing.

· Anisotropy: Due to the ordered molecular structure, LCER displays anisotropic properties (mechanical, optical, or electrical), with performance varying significantly in different directions.

2. Superior Mechanical Properties

· High Strength and Toughness: The ordered molecular structure results in higher tensile strength, modulus, and fracture toughness compared to conventional epoxy resins.

· Fatigue Resistance: LCER’s molecular structure enhances its ability to withstand cyclic stress, making it ideal for high-performance composite materials.

3. Excellent Thermal Properties

· High Thermal Stability: LCER typically has a higher glass transition temperature (Tg) and thermal decomposition temperature, offering superior heat resistance compared to standard epoxy resins.

· Low Thermal Expansion: The ordered liquid crystal structure reduces the coefficient of thermal expansion, ensuring dimensional stability for high-precision applications.

4. Electrical and Optical Properties

· Electrical Insulation: LCER retains the excellent electrical insulation properties of epoxy resins, making it suitable for electronic encapsulation and insulating coatings.

· Optical Anisotropy: The liquid crystal structure imparts unique optical properties, such as birefringence, which can be utilized in optical devices or display technologies.

5. Low Shrinkage and Processability

· Minimal Shrinkage: LCER exhibits extremely low volume shrinkage during curing (sometimes near zero), making it ideal for high-precision molding and microelectronics.

· Controllable Curing: The curing process and final material properties can be precisely tailored by adjusting the liquid crystal phase and curing agents.

6. Chemical Stability

· LCER inherits the chemical resistance of epoxy resins, offering excellent resistance to acids, alkalis, and solvents, suitable for harsh environments.

Applications

Due to its combination of liquid crystal and epoxy resin properties, LCER is used in:

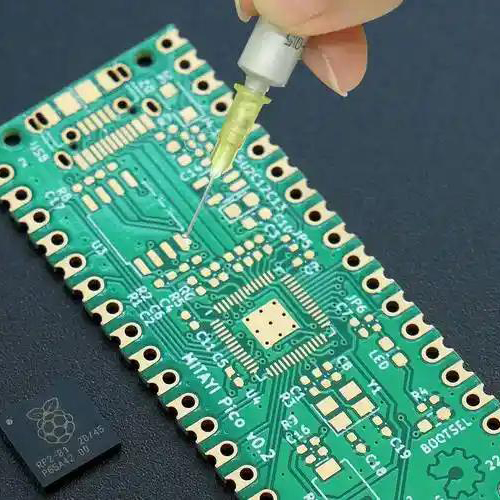

· High-thermal-conductivity epoxy adhesive for PCB bonding

It can be used as a substrate material or coating material for PCBs, enhancing the PCB's heat resistance, mechanical strength, and electrical performance. Its low coefficient of thermal expansion helps reduce dimensional changes in the PCB during temperature variations, improving the PCB's reliability and stability.

· Epoxy adhesive for electronic packaging

Liquid crystal epoxy resin has excellent heat resistance, dielectric properties, and dimensional stability, making it suitable for encapsulating electronic components to protect them from environmental factors and ensure the normal operation of electronic devices. For example, in the encapsulation of integrated circuits, semiconductor devices, and similar applications, it provides reliable protection and insulation performance.

· Used for Chip Bonding

Underfill: During the chip packaging process, the gap between the chip and the substrate needs to be filled with a material to enhance the chip's mechanical strength and reliability. Liquid crystal epoxy resin, with its excellent flowability and bonding properties, can be used as an underfill material to fill the gap between the chip and the substrate. This ensures a strong bond between the chip and the substrate, improving the chip's resistance to impact and vibration.

Chip Attachment: Liquid crystal epoxy resin can be used to attach the chip to the substrate, securing the chip in place. Compared to traditional adhesives, liquid crystal epoxy resin offers higher bonding strength and heat resistance, ensuring that the chip remains firmly attached and does not loosen or detach during long-term use.

· Manufacturing Encapsulation Molds

Molding Dies: In the electronic encapsulation process, molds are used to form the encapsulation housing. Liquid crystal epoxy resin, with its excellent processability and dimensional stability, can be used to create encapsulation molds of various shapes and sizes. Molds made from liquid crystal epoxy resin offer high precision and excellent surface finish, meeting the stringent requirements of electronic encapsulation.

Potting Molds: In certain specialized electronic encapsulation processes, potting molds are used to encapsulate electronic components with liquid crystal epoxy resin. These molds require excellent sealing properties and high-temperature resistance to ensure that the liquid crystal epoxy resin is effectively potted into the electronic components without leakage or deformation during the curing process.

· Aerospace Applications

Composite Materials

Liquid crystal epoxy resin can be combined with reinforcing materials such as carbon fiber or glass fiber to produce high-performance composite materials. These composites offer high strength, high modulus, and excellent high-temperature resistance, making them suitable for manufacturing aircraft structural components, engine parts, missile casings, and more.

Adhesives and Coatings

In the aerospace sector, adhesives and coatings must meet stringent performance requirements. Liquid crystal epoxy resin, with its excellent bonding properties and corrosion resistance, can be used for structural bonding and surface coatings in aircraft, enhancing structural strength and corrosion resistance.

Technical Specifications of Liquid Crystal Epoxy Resin

|

Index |

ITCE04 |

ITCE05 |

Test Method/Standard |

|

Core Indicators |

|||

|

Purity |

≥85 |

≥85 |

Liquid Chromatography |

|

Non-core Indicators |

|||

|

Epoxy Value |

≥0.56mol/100g |

≥0.3mol/100g |

GB-T1677-2008 |

|

Melting Point (℃) |

≥110 |

≥110 |

DSC |

|

Solubility |

Easily soluble |

Easily soluble |

Balance weighing |

|

Structure |

Biphenyl type |

Methylene type |

|

|

Other Structures |

Aromatic ester type |

||

Technical Indicators of Cured Liquid Crystal Epoxy Resin

|

Index |

ITCE04 |

ITCE05 |

Test Method/Standard |

|

Core Indicators |

|||

|

Thermal Conductivity (W/(m·K)) |

0.4(APAB) |

0.5(APAB) |

ASTM-D5470 |

|

Dielectric Constant |

≦ 4 |

≦ 4 |

GB/T 31838.6-2021 |

|

Melt Viscosity (cps) |

≦ 100 (190℃) |

≦ 100 (190℃) |

Rotational Viscometer |

|

Tg (℃) |

≥ 170 |

≥ 170 |

DMA |

|

5% Thermal Decomposition Temperature (℃) |

≥ 320 |

≥ 320 |

TG |

|

Non-core Indicators |

|||

|

Tensile Strength |

≥ 50MPa |

≥ 60MPa |

ASTM-D882 |

|

Young's Modulus |

≥ 1.5GPa |

≥ 2GPa |

ASTM-D882 |